3D at Depth Completes 300 Offshore LiDAR Metrologies

Partnership News / 30/01/2018

End Users Continue to Embrace Greater Value from Long Range, Touchless Subsea LiDAR Surveys

LONGMONT, Colo., Jan. 30, 2018 (GLOBE NEWSWIRE) -- 3D at Depth Inc., a global provider of advanced subsea LiDAR (SL) systems and survey support services, announced today the company has completed its 300th subsea LiDAR spool metrology. The subsea LiDAR measurement, conducted offshore within the Mediterranean Sea, covered 8 long spool metrologies with lengths greater than 90m and was completed in 24 hours. The project delivered considerable savings overall for the EPIC installation contractor and provided valuable 3D data for the oil and gas major (end user). 3D at Depth is the world’s leading expert in subsea LiDAR technology and first introduced subsea LiDAR metrologies for the offshore market 3.5 years ago in the Gulf of Mexico. This 300th metrology marks a significant milestone in the offshore survey market, as customers continue to see the clear advantages of subsea LIDAR laser metrologies over traditional laser scanning and conventional methods.

“We are excited to have reached this milestone,” stated Neil Manning, Chief Business Development Officer, 3D at Depth. “The Company has been committed to innovation and collaboration with oil and gas majors from the inception. As a result, this relationship has produced an IMCA-approved process for the utilization of our technology. Another exciting development for us is a joint presentation with Shell UK at Subsea Expo February, 7th at the Aberdeen conference center (AECC) between 14:00 and 16:30. The presentation is called ‘The New Metrology’ and focuses on a collaboration project at the Gannet C installation.”

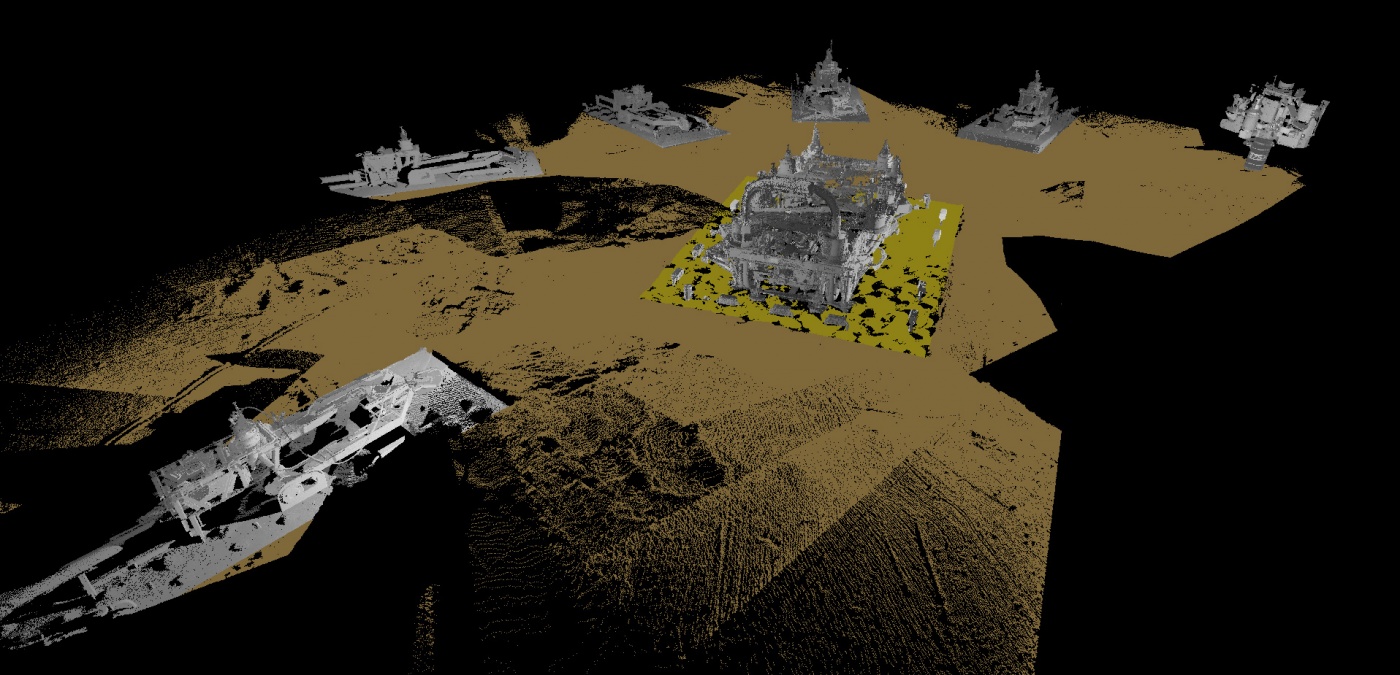

To date, the Company has conducted metrology projects in the US, Europe, Mediterranean and Asia and has operated in up to 4,000 meters in depth. Each 3D at Depth subsea LiDAR (SL) laser system is powered by proprietary point cloud processing software with in-house patented technology and a customized optical design. The success of 3D at Depth’s metrology process is based on the unique features of subsea LiDAR technology which includes touchless, total beam control scans, multi-return Time of Flight (TOF) data formats and ranges up to 45 meters during the data collection process.

From a client deliverable standpoint, every 3D at Depth LiDAR metrology delivers precise, repeatable, millimetric 3D point cloud data sets that can be easy imported into any existing GIS or CAD-based platform, providing an unparalleled baseline of subsea assets at the point of installation. (Reflectivity and longer-range measurement repeatability are unique features attributed to 3D LiDAR data sets and are essential for more precise 3D modeling, analysis and visualization.)

3D at Depth’s metrology projects have provided critical information in the areas of cost avoidance, risk mitigation and asset integrity. Subsea LiDAR data sets provide a variety of 3D intelligence beyond metrology. These applications include validating as-built design data vs. the actual structure design for asset integrity; generating physical 3D 1:1 printed scale models for wellhead fabrication, and quantifying potential risk hazards in the areas of vibration and subsidence. The Company is developing additional LiDAR technology applications in the areas of leak detection, decommissioning, new field development and non-touch subsidence and asset condition monitoring.

The Company made recent news with the development of an immersive collaboration 3D LiDAR VR Platform “Powered by IQ3” that connects multiple users and key decision makers to their 3D subsea data via any laptop, desktop or smart device through a secure web portal.

3D at Depth will be conducting workshops and demonstrations during Oceanology International 2018 in London at Stand G250. Visitors who participate in the workshop will receive a pair of 3D goggles.

LONGMONT, Colo., Jan. 30, 2018 (GLOBE NEWSWIRE) -- 3D at Depth Inc., a global provider of advanced subsea LiDAR (SL) systems and survey support services, announced today the company has completed its 300th subsea LiDAR spool metrology. The subsea LiDAR measurement, conducted offshore within the Mediterranean Sea, covered 8 long spool metrologies with lengths greater than 90m and was completed in 24 hours. The project delivered considerable savings overall for the EPIC installation contractor and provided valuable 3D data for the oil and gas major (end user). 3D at Depth is the world’s leading expert in subsea LiDAR technology and first introduced subsea LiDAR metrologies for the offshore market 3.5 years ago in the Gulf of Mexico. This 300th metrology marks a significant milestone in the offshore survey market, as customers continue to see the clear advantages of subsea LIDAR laser metrologies over traditional laser scanning and conventional methods.

“We are excited to have reached this milestone,” stated Neil Manning, Chief Business Development Officer, 3D at Depth. “The Company has been committed to innovation and collaboration with oil and gas majors from the inception. As a result, this relationship has produced an IMCA-approved process for the utilization of our technology. Another exciting development for us is a joint presentation with Shell UK at Subsea Expo February, 7th at the Aberdeen conference center (AECC) between 14:00 and 16:30. The presentation is called ‘The New Metrology’ and focuses on a collaboration project at the Gannet C installation.”

To date, the Company has conducted metrology projects in the US, Europe, Mediterranean and Asia and has operated in up to 4,000 meters in depth. Each 3D at Depth subsea LiDAR (SL) laser system is powered by proprietary point cloud processing software with in-house patented technology and a customized optical design. The success of 3D at Depth’s metrology process is based on the unique features of subsea LiDAR technology which includes touchless, total beam control scans, multi-return Time of Flight (TOF) data formats and ranges up to 45 meters during the data collection process.

From a client deliverable standpoint, every 3D at Depth LiDAR metrology delivers precise, repeatable, millimetric 3D point cloud data sets that can be easy imported into any existing GIS or CAD-based platform, providing an unparalleled baseline of subsea assets at the point of installation. (Reflectivity and longer-range measurement repeatability are unique features attributed to 3D LiDAR data sets and are essential for more precise 3D modeling, analysis and visualization.)

3D at Depth’s metrology projects have provided critical information in the areas of cost avoidance, risk mitigation and asset integrity. Subsea LiDAR data sets provide a variety of 3D intelligence beyond metrology. These applications include validating as-built design data vs. the actual structure design for asset integrity; generating physical 3D 1:1 printed scale models for wellhead fabrication, and quantifying potential risk hazards in the areas of vibration and subsidence. The Company is developing additional LiDAR technology applications in the areas of leak detection, decommissioning, new field development and non-touch subsidence and asset condition monitoring.

The Company made recent news with the development of an immersive collaboration 3D LiDAR VR Platform “Powered by IQ3” that connects multiple users and key decision makers to their 3D subsea data via any laptop, desktop or smart device through a secure web portal.

3D at Depth will be conducting workshops and demonstrations during Oceanology International 2018 in London at Stand G250. Visitors who participate in the workshop will receive a pair of 3D goggles.